Titanova, Inc. is an ISO 9001:2015 certified laser job shop spanning 14,400 square feet, with 12,000 square feet dedicated to manufacturing. Our facility offers ample space for large projects. We can handle components up to 45 feet long and 10 feet wide with a 35,000 lbs. lift capacity, accommodating a wide variety of client needs. Titanova’s strong infrastructure includes semi-truck drive-in and dock-high shipping capabilities, allowing us to manage logistics efficiently.

Titanova Flexible Equipment Capability

At Titanova, we combine advanced laser processing technologies with flexible equipment, making us capable of handling a range of tasks across industries. We use nine multi-axis robotic systems, each integrated with direct diode and fiber-coupled lasers that provide up to 6,000W of power. These systems allow us to perform complex tasks with ease, from laser welding services to laser surface restoration.

Our custom production systems are specifically built to meet the exact needs of various industries. For example, we have systems that focus on laser cladding and heat treating diesel pistons, as well as laser welding of smaller components. These capabilities give us an edge in performing precision tasks and adapting to different client requirements. We’re able to provide metal machining services that complement our laser work, delivering both laser welding and machining in a single streamlined process.

Laser Surface Restoration

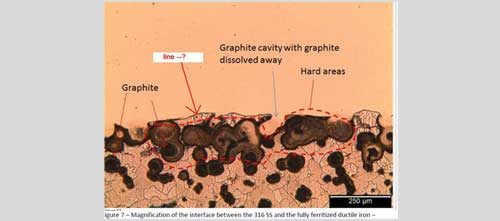

Titanova specializes in laser surface restoration, a highly effective method for repairing and enhancing the surfaces of worn components. This process is particularly useful for industries that need to extend the lifespan of their machinery and equipment.

Laser cladding, a key aspect of surface restoration, involves applying a protective metal layer to components. This process can repair worn-out surfaces, improve corrosion resistance, and reduce wear, restoring components to their original or even improved condition. Laser surface restoration is beneficial for industries like aerospace, automotive, and heavy equipment, where equipment reliability is critical.

Laser Welding Services

Another core service Titanova offers is laser welding services. Our diode lasers provide high-speed, precise welding with minimal distortion. Laser welding is ideal for joining thin-gauge metals, stainless steel, and other materials that might be challenging with traditional welding methods. The precision offered by laser welding ensures tight joints without the heat distortion common in conventional techniques. Titanova’s advanced equipment ensures that clients receive a solution that is both efficient and cost-effective. We have worked with various industries to deliver reliable, high-quality welding solutions.

Metal Machining Services

Titanova also offers metal machining services that support our laser processing work. With our CNC and manual machining capabilities, we handle various types of materials and sizes. These services complement our laser processes, making sure that clients receive finely tuned and highly accurate components. Whether it’s machining parts for laser welding or finishing off components post-cladding, our machining services guarantee high-quality results that meet industry standards.

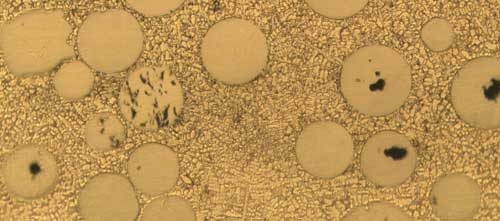

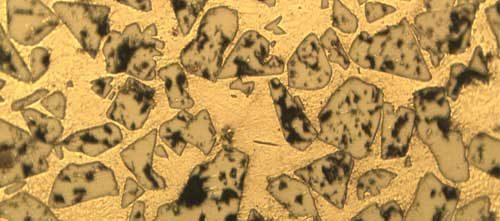

Metallurgical and Quality Assurance Equipment

Titanova places great emphasis on quality control. We employ a range of metallurgical and quality assurance equipment to monitor and verify the integrity of materials and processes. This includes tools like the XRF elemental analyzer, Leeb portable hardness tester, and Rockwell hardness testers. These tools allow us to guarantee that every piece of equipment we work on meets the highest standards, whether it’s a laser-cladded part or a welded component. Our inspection tools, such as the 50X binocular microscope and 200X toolmaker’s microscope, provide additional layers of quality control, guaranteeing that clients receive the best possible results.

Elevate Your Manufacturing with Titanova!

Titanova, Inc. offers a comprehensive range of laser and machining services, including laser surface restoration, metal machining services, and laser welding services. Our advanced equipment, experienced team, and commitment to quality make us a reliable partner for industries seeking precision and efficiency in their manufacturing processes. Contact us today to learn more about how we can help with your next project.