- Agriculture and Farming

Agriculture and Farming

Agricultural machinery, which operates in tough field conditions, benefits significantly from Titanova’s advanced laser services. Laser hardfacing is commonly used on plow blades, harvester teeth, and cultivator shanks, providing a durable surface that resists abrasion from soil and crops. These machines endure the constant friction and pressure encountered in the field.

The use of carbide overlays and wear-resistant coatings on mowers, chippers, and combines helps frequency of repairs and ensures that farming operations run smoothly without extended downtime.

- Chemical Processing / Cement Production

Chemical Processing / Cement Production

In the chemical processing and cement production industries, components face exposure to corrosive substances and abrasive conditions. Titanova’s laser cladding services are ideal for applying corrosion-resistant weld overlays on critical parts like mixing tanks, piping systems, and reactor vessels, ensuring they remain intact under harsh chemical environments.

For components like conveyor belts, crusher parts, and kiln linings, our laser hardfacing services, with carbide overlays, provide the wear resistance necessary to extend the life of equipment that handles abrasive materials.

- Mining

Mining

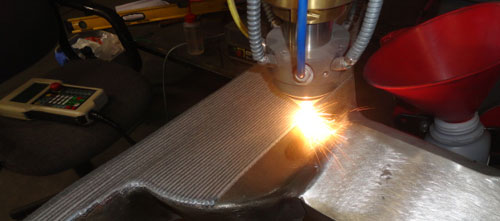

Mining equipment operates in some of the harshest environments, requiring high durability and protection from constant wear. Titanova’s laser hardfacing applies carbide overlays on components like excavator buckets, drill bits, and shovels, allowing them to resist the intense abrasion caused by rocks and other hard materials. Wear-resistant coatings are applied to crusher parts, screening panels, and caterpillar tracks, ensuring long-lasting performance and reducing downtime in operations. This technology not only increases the lifespan of critical mining tools but also helps to reduce maintenance costs.

- Marine

Marine

Marine components must endure the corrosive effects of saltwater, as well as heavy mechanical stress. Titanova’s corrosion-resistant overlays are applied to components like propellers, rudders, and hull plating through laser cladding, particularly with materials like bronze, which are known for their resistance to corrosion.

Our laser surface restoration technology is ideal for restoring worn-out marine engine parts, shafting, and deck equipment, returning them to service with enhanced durability. This process helps minimize the downtime of marine vessels, ensuring they continue to perform efficiently and cost-effectively.

- Energy and Recovery Production

Energy and Recovery Production

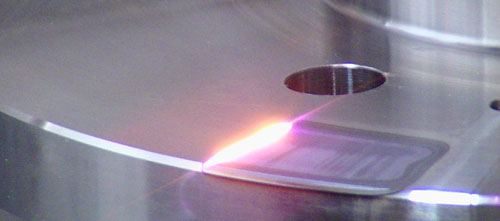

The energy sector often involves components subjected to high temperatures and corrosive environments. Laser cladding is used to apply corrosion-resistant weld overlays to key equipment such as heat exchangers, turbine blades, and valve seats, protecting them from both chemical corrosion and thermal degradation.

Laser hardfacing with carbide overlays is applied to pump impellers, compression rings, and mixer blades, reducing wear from the movement of abrasive particles in liquids and gases. These services ensure the longevity and efficiency of critical energy equipment, reducing the frequency of repairs and replacements.

- Heavy Equipment and Machinery

Heavy Equipment and Machinery

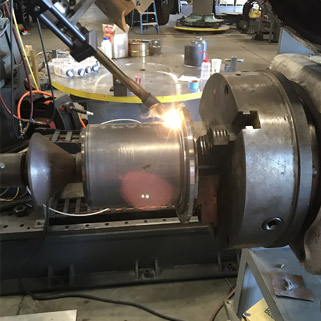

Heavy equipment must perform reliably under extreme conditions, making durability and wear resistance critical. Titanova provides laser cladding, heat treating, and remanufacturing services to protect and restore key components across the heavy equipment industry.

Our low-heat laser cladding process applies wear-resistant overlays to parts like engine blocks, gearboxes, and chassis components, while our cast iron weld overlay service restores structural integrity to worn or cracked iron-based parts. Damaged components such as gears, valves, and bearing housings are rebuilt to original specifications through precision laser remanufacturing.

We also use laser heat treating to harden high-wear surfaces like loader arms, bucket teeth, and track pads, and offer laser welding for refurbishing worn rotors, stators, and windings in industrial motors. From bulldozers and excavators to cranes, Titanova’s laser solutions help heavy machinery perform longer and more reliably in the toughest environments.

- Transportation

Transportation

In the transportation industry, components such as railroad tracks, wheels, and braking systems need to be both durable and resistant to wear and corrosion. Titanova’s laser restoration of railroad components includes laser surface restoration, which helps to rejuvenate worn-out rail parts.

Our laser cladding service is used to apply manganese coatings to railroad components to protect against impact and wear. We also specialize in laser additive repair for locomotive engine parts, axles, and carriages, restoring these critical components to their original strength and functionality.

- Automotive

Automotive

The automotive industry demands precision and durability in every part, from engine components to body panels. Titanova’s laser cladding and low heat welding services are used to create strong, wear-resistant surfaces on parts like cylinder heads, valves, and camshafts. These techniques prevent distortion while enhancing the strength of the components.

Laser heat treating and laser tempering are applied to gears, sprockets, and brake components to improve their hardness and resistance to fatigue. These services help the automotive industry meet performance standards while minimizing wear over time.

Services Offered by Titanova, Inc.

Titanova provides specialized laser solutions for enhancing industrial components:

Rebuild, Reinforce, Revive with Titanova!

Titanova, Inc. is dedicated to providing advanced laser solutions for industries that rely on durable, high-performance machinery. Our expertise in laser surface restoration, metal machining services, laser welding services, and laser cladding services allows us to offer precise, cost-effective solutions that extend the life of critical equipment. Contact us today to find out how we can help your business maintain its equipment and improve its efficiency.