As a leading provider of laser processing solutions, customers come to Titanova for innovative solutions for their laser heat treating, laser welding, laser hard facing, laser cladding, and other laser processing applications. We offer value-added metallurgical analysis services in combination with our laser processing services.

Titanova, Inc. is an ISO 9001:2015 certified supplier with full-service metallurgical and metallographic capabilities, allowing us to give our customers immediate production quality assurance. Our in-house quality assurance services allow us to efficiently and cost-effectively develop novel laser processes for customers. This unique range of capabilities, combined with our in-depth knowledge of laser processing, saves a tremendous amount of time and money for our customers.

Our primary mission is to reduce customer risk, and our quality assurance capabilities are one of the cornerstones to accomplishing that mission. Since our inception, Titanova has continuously built a knowledge database of laser processed material properties. We are continually exploring new and higher-performing materials to solve our customer’s toughest applications.

What is Metallurgical Analysis?

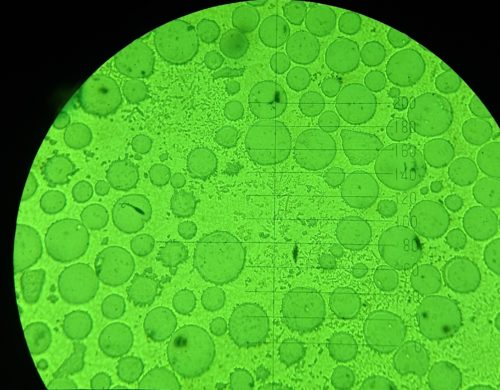

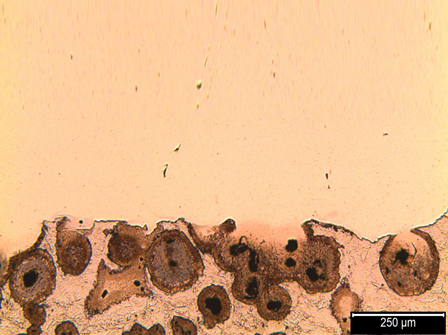

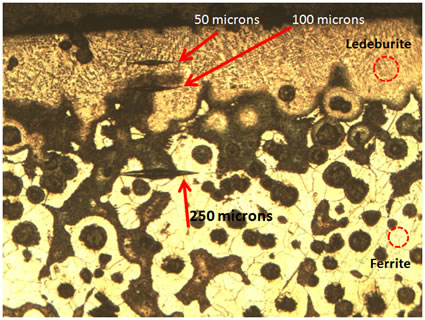

Metallurgical analysis is the process of understanding a material’s internal structures and weaknesses to determine how or why it reacts a certain way during laser processing. As the metals are subjected to various laser processes, such as heat treating or welding, their material properties are affected. Analyzing these changes enables us to quickly develop the optimum laser process to achieve the desired outcomes for our clients. In addition, this capability allows the detection of internal or surface flaws, evaluation of the microstructure, and evaluation of the metal chemistry.

Metallurgical Services from Titanova

Titanova offers a wide range of metallurgical services, including but not limited to:

- Machining evaluations

- Comparative material analyses (Chemistry)

- Design review

- Failure analysis

- First article inspection

- Heat treat response

- Material research

- Process development

- Process verification

- Bond analysis

- Quality assessment

- Quality control

- Weld evaluations

- Reverse engineering

- Substantiation analysis of welds or other processes

- Erosion analysis via laser hardfacing

What to Expect from Titanova Metallurgical Analysis Services

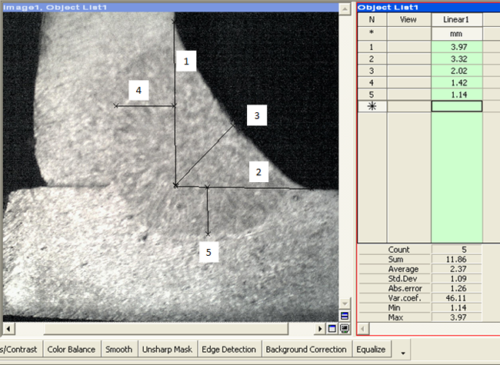

The benefit of combining laser processing and metallurgical analysis providers is that we use this knowledge to help clients understand what the laser process is doing. Since the laser processes are typically surface only, we use metallurgical services to see laser heat treating, laser cladding, laser hardfacing, and laser welding results. This is documented for process development reports, quality assurance purposes, and R&D development.

Metallurgical Equipment

Titanova offers access to the following state-of-the-art metallurgical testing equipment:

- Knoop and Vickers micro-hardness testing equipment

- Rockwell and Leeb rebound type macro-hardness measuring capability

- X-ray fluorescence alloy to chemically analyze laser cladding dilution

- Surface roughness testing

- Metallurgical etching (Metallographic analysis)

Industries Served

Many industries benefit from Titanova’s full range of laser processing and metallurgical analysis services, including:

- Aerospace

- Agriculture

- Automotive

- Chemical processing

- Coal

- Construction

- Energy and recovery

- Food processing

- Heavy equipment

- Marine

- Mining

- Nuclear energy

- Oil recovery and refining

- Pulp and paper

- Remanufacturing

- Steel manufacturing

- Transportation

Titanova, Inc. is a full-service, ISO 9001:2015 certified laser job shop, with extensive expertise in laser processing in combination with comprehensive quality assurance and metallurgical capabilities. Contact Titanova today for more information about our metallurgical analysis services.