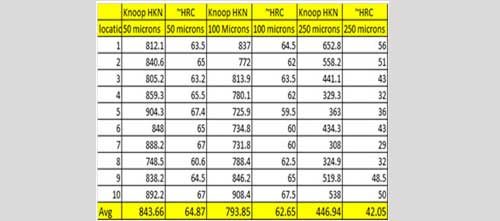

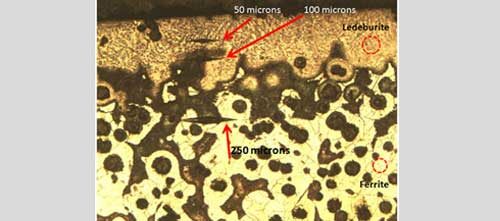

Titanova has a long list of production parts that are case hardened with negligible distortion by laser transformation hardening. There are some materials, such as nodular irons, with an entirely ferritic matrix that present a unique surface modification challenge. Ferritic ductile irons are highly desirable due to their high ductility. However these grades require several minutes at 1600F in order to be fully hardened. Thus ferritic ductile iron is not amenable to case hardening. Titanova Inc, has developed a new process that produces a robust super hard crack free surface with high lubricity. This is known as laser glazing. Laser glazing involves melting a thin surface layer of cast iron followed by rapid solidification. The resulting surface is super-hard, crack free and possesses high lubricity, becoming “metallic glass”. This phase of iron-carbon is known as ledeburite, which is a cementite-martensite and retained austenite composition that has very hard properties, typically greater than > 60 HRC. The depth of this glazed layer is approximately 100 microns. The robustness of the laser-glazed surface is partially due to the unique interface between the bases ferrite and pearlite with carbon nodules. As seen in the bottom right image, the ledeburite interface does not have sharp stress risers, therefore any stresses lines between the ledeburite layer and the base are not as susceptible to cracking.