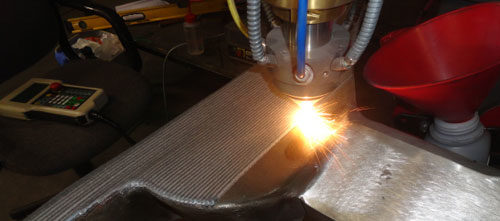

Laser hardfacing is a precise welding method for applying wear-resistant material to metal surfaces. This process uses a high-powered laser to weld a thin, controlled layer of hard material onto critical components. It strengthens surfaces exposed to abrasion, erosion, or impact, extending service life with minimal heat input and distortion.

Laser hardfacing isn’t just for new parts. It’s often used to refurbish worn components, restoring them to functional condition or better. This reduces waste and total cost of ownership. With precise overlays, worn surfaces can be recovered without removing excess base material.

Purpose of Hard Coating

Hard coatings are essential for protecting components that operate in harsh environments. These coatings form a durable surface barrier that resists wear and mechanical stress. Laser hardfacing provides a reliable hard coating by forming a metallurgical bond without compromising the base material. This helps retain the structural integrity of parts even after repeated use.

What Is a Carbide Overlay?

A carbide overlay is a wear-resistant surface layer composed of hard particles—such as tungsten carbide—embedded in a metal matrix. These overlays are valued for their extreme hardness and ability to withstand high-wear environments. Laser hardfacing allows for consistent application of carbide overlays with minimal dilution and high carbide retention, often up to 65%, but even higher weight percentages are possible. This results in strong, long-lasting protection.

Process Benefits

Titanova’s laser hardfacing process produces clean overlays with precise thickness control. The method delivers a smooth finish that requires little to no post-processing. Because the heat input is tightly controlled, parts maintain their shape, and internal stresses are reduced. Compared to traditional welding, laser hardfacing offers greater consistency and fewer rework issues.

Common Applications

Many industries benefit from laser hardfacing.

- Agriculture: Used on plow blades, augers, and cultivator shanks to resist abrasive soil wear. The hard coating extends equipment life and reduces maintenance.

- Mining and Construction: Ideal for reinforcing bucket edges, drilling tools, and wear plates exposed to rock, gravel, and high-impact surfaces. Carbide overlays help prevent premature failure.

- Oil and Gas: Applied to pump housings, valve parts, and other components that handle abrasive slurries. Laser hardfacing improves resistance to erosion and wear from high-pressure fluids.

Comparison with Other Methods

- Less Heat, Less Distortion: Unlike traditional welding, laser hardfacing produces minimal heat input, reducing the risk of warping or structural damage.

- Higher Bond Strength: Laser-applied overlays form a metallurgical bond with the base material, providing greater durability and fewer chances of delamination.

- Cleaner Carbide Overlay: The process preserves carbide content more effectively, creating a harder, more consistent surface compared to conventional methods.

- Reduced Post-Processing: Finished surfaces are smoother and often require little to no machining after application, saving time and cost.

Available Alloys and Materials

Titanova offers a range of materials suitable for laser hardfacing. These include tungsten carbide, Stellite®, cobalt alloys, and iron carbide based hardfacing alloys . Selection depends on the cost and the working environment—abrasion, impact, corrosion, or high temperature. Each carbide overlay is cost effectively selected to match the wear mechanism expected during use.

Quality Control and Testing

All overlays are supported by in-house metallurgical testing. Quality checks include hardness mapping, microstructure analysis, and alloy verification. This ensures that every hard coating meets performance standards and holds up in field conditions.

Don’t Replace It, Laser Hardface It with Us

Titanova welcomes inquiries from companies looking to protect or repair critical components. To begin, share details such as part dimensions, material type, and working environment by contacting us today. The team will recommend a hard coating and carbide overlay solution that matches your needs.