Here at Titanova, we’ve spent over 40 years mastering the art of metal surface restoration and enhancement. Backed by ISO 9001:2015 certification, our team applies cutting-edge laser cladding techniques to restore worn parts and build custom overlays that stand up to the harshest wear, corrosion and thermal conditions. With our laser cladding services, you get turnkey support, from initial consultation through final certification, so your components meet or exceed their designed service life.

Our Expertise

with precision motion systems. By integrating automation and metallurgy knowledge, we maintain sub-0.010″ tolerances in a single pass, eliminating the trial-and-error of multi-layer weld buildups.

How the Laser Cladding Process Works

Before you see any laser light, we prepare each part by degreasing, grit-blasting and/or preheating to eliminate contaminants and reduce thermal shock. During deposition:

- Melt pool control: A focused beam creates a narrow melt pool.

- Alloy feeding: Powder or wire is metered into the pool at rates up to 10 lb/hr, preserving the engineered chemistry.

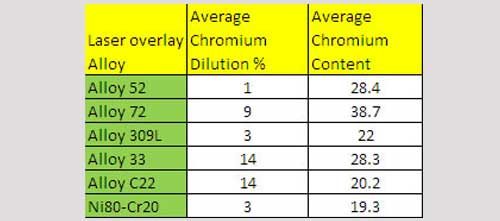

- Rapid solidification: Controlled cooling yields a dense, crack-resistant microstructure with dilution kept under 5%.

- Dimensional accuracy: Each pass deposits 0.010″–0.080″ of overlay while maintaining planar tolerances of ±10% of the deposition thickness″.

This optimized laser cladding process fuses your chosen alloy, nickel-chromium superalloys, cobalt alloys or carbide composites, directly to the substrate, creating a homogeneous structure that outperforms conventional weld overlays in fatigue, abrasion and corrosion resistance.

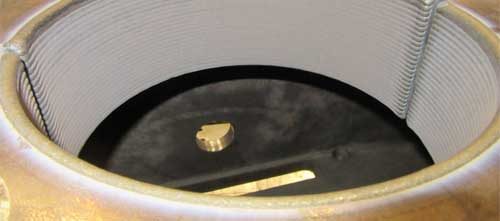

Laser hardfaced bit holders

Service Capabilities

Our laser cladding services cover both repair and new-build applications:

Component Repair & Remanufacturing

Restore journals, shafts, valve seats and sealing faces to near-net geometry without warping or cracking.

Surface Enhancement

Apply nickel-chromium superalloys, cobalt-based alloys or carbide-reinforced composites for extreme wear and corrosion resistance.

Custom Alloy Development

Work with our metallurgists to formulate custom alloys or blends of Inconel®, Hastelloy™, Stellite® or tungsten carbide tailored to your environment.

<Learn about the difference between hardfacing and cladding.>

Industries We Serve

We’ve applied our laser cladding expertise across a broad spectrum of heavy-duty environments:

Oil & Gas

Repairing and reinforcing pump impellers, valve trim, drill collars and downhole tooling to withstand abrasive particulates and corrosive well fluids.

Power Generation

Repair turbine blade roots, boiler feed pump shafts and seal faces in which oxidation resistance and dimensional accuracy are important under high temperature cycling.

Rail & Heavy Equipment

The life of crossing frogs, wheel flanges, bucket teeth and forging dies can be extended by ferro manganese overlays

Hydraulics and Pneumatics

Hard laser clad overlays to replace chrome plating on cylinder rods, bearing journal and piston-faces to yield a lower cost low wear surfaces.

Quality Assurance & Support

Our commitment to precision doesn’t stop when the laser switches off. Every component completes a rigorous inspection regimen:

- Non-Destructive Testing: Ultrasonic scans and dye-penetrant checks identify subsurface anomalies.

- Hardness Mapping: We verify that cladding hardness meets or exceeds your specs, ensuring long-term wear resistance.

- Metallography: Microstructure analysis confirms consistent alloy distribution and minimal dilution.

- Documentation: Detailed process logs, material certifications and final inspection reports provide full traceability.

Throughout, your dedicated project engineer coordinates trials, test coupons and final acceptance, so you always know where your parts stand.

Why Choose Our Laser Cladding Services?

When you need more than a quick fix, our team delivers end-to-end precision and reliability, from initial metallurgy consultation to final certification:

- Proven Expertise: Over 40 years of hands-on surface engineering.

- Rapid Turnaround: Single-pass overlays in robotic cells.

- Cost Savings: Tight process control reduces powder use, scrap and machining.

- Full Partnership: One point of contact overseeing everything, from alloy selection to delivery.

Together, automation, real-time monitoring and deep metallurgical know-how ensure our laser cladding consistently outperforms traditional methods in durability and dimensional accuracy.

Transform Wear Into Reliability

At Titanova, we do not simply repair parts, we transform them. We use a very defined laser cladding process which combines sophisticated automation with old fashioned metallurgy to provide unsurpassed wear resistance, corrosion proofing and +/-0.010” tolerance. Our turnkey laser cladding system services integrate robot refinements, in-process surveillance and stringent quality inspections to ensure every component meets your most demanding requirements and stays operational longer.

Contact us today or request a quote to boost your performance and uptime.