Titanova Inc. has more than 40 years of experience in laser material processing and specializes in precise non-contact surface hardening through laser heat treating services. Our ISO 9001:2015 certified operation provides metallurgically controlled solutions to customers who need enhanced wear resistance and increased hardness and reduced distortion in their mission-critical components. The laser heat treating process delivers exact results with high efficiency and consistent outcomes for complex shapes and difficult materials.

How Laser Heat Treating Works

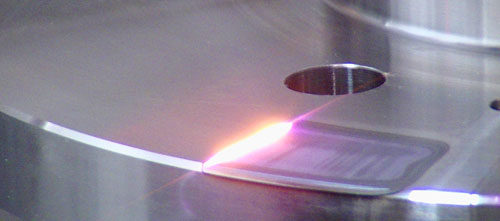

The thermal process of laser heat treating involves heating specific metal surface areas above transformation temperatures through high-powered laser energy. The material undergoes rapid self-quenching which results in martensite formation that produces surface hardness increases while maintaining base material properties. The heat-affected zone (HAZ) receives precise control through laser processing which produces less thermal distortion than induction or flame hardening methods. The process works best for parts with complex shapes and strict size requirements and situations that need targeted surface modification.

The Role of Laser Tempering in Metallurgical Control

To further enhance results, laser tempering is used post-hardening to reduce residual stress and refine the microstructure. By applying controlled secondary heating, we can improve toughness without sacrificing hardness. This is especially valuable in applications where fatigue strength and dimensional stability are critical. At Titanova, we integrate laser tempering directly into our laser heat treating workflow, giving our clients better control over the final properties of their parts in a single, streamlined process.

Laser Heat Treating Cost Advantage

Titanova diode laser heat treating service is a much more cost effective heat treating technique when compared to traditional heat treating processes when one considers first time quality, turnaround time, pre and post part processing requirements. The diode laser heat-treating process is inherently a LEAN (single piece flow) process. Since diode laser heat treating is a localized heat treat, only where the laser beam points, distortion can be significantly reduced or eliminated. For ferritic cast irons we use a laser glazing process. Learn more about Laser Glazing here.

Key Technical Specifications for Laser Heat Treating

Titanova uses cutting-edge equipment and in-house developed process controls to ensure high-performance outcomes across all materials and geometries. Our technical capabilities include:

- Laser Power: Up to 10 kW, diode laser technology

- Spot Sizes: Adjustable from 1 mm to 10 mm

- Hardening Depth: 0.020″ to 0.080″ (0.5 mm to 2 mm), material-dependent

- Target Hardness: Up to 65 HRC depending on alloy

- Cooling Methods: Self-quenching or supplemental air/gas cooling

- Positioning Precision: ±0.001″ via CNC and robotic motion systems

- Material Compatibility:

- Carbon steels

- Alloy steels

- Stainless steels

- Ductile iron

- Tool steels

- Select cast irons

<Learn more about the benefits of the laser hardening process.>

Application Areas and Industries Served

Our laser heat treating services support a range of industries that require localized hardening without the drawbacks of bulk heat treatments. We serve clients across:

- Aerospace (landing gear components, tooling interfaces)

- Automotive (cam lobes, crank journals, transmission parts)

- Oil & gas (valve seats, actuator arms, downhole tools)

- Heavy equipment (rollers, gears, wear plates)

- Defense and firearms (barrels, bolt carriers, breech faces)

The non-contact nature of laser heat treating makes it ideal for parts with detailed geometries or post-machined features that must retain tolerances.

Performance Advantages Over Traditional Methods

Titanova’s laser-based approach offers several key benefits over traditional thermal hardening:

- Minimal to zero part distortion

- No masking or post-processing required

- Narrow, repeatable HAZ with high depth-to-width ratio

- Integration with automation for high throughput

- Environmentally cleaner with no open flames or chemical baths

These advantages translate to reduced rework, lower scrap rates, and higher component integrity, especially on precision components where dimensional stability is non-negotiable.

Precision That Protects Your Bottom Line

Titanova delivers advanced laser heat treating services and laser tempering processes which combine precision with durability and production efficiency. Our services enable manufacturers to minimize distortion and extend part life and reduce rework while maintaining tight tolerances and material integrity for high-performance steel alloys and intricate geometries that need selective hardening.

Reach out to us now to get a quote and learn how Titanova’s laser expertise will enhance the reliability of your essential components.