Welding involves joining two metal parts using heat to melt them together. Weld overlay involves adding to the surface of a metal component to recover lost dimensions [ Additive remanufacturing] or changing the chemistry of the metal surface [ corrosion resistance]. Using the laser as the heat source, hot and cold wire feed welding are two types of laser welding processes that can be used to supply metal material to the weld puddle. For laser welding it is primarily for improved weld root enforcement, and for laser weld overlay it is for cladding the part. Though like gas tungsten arc welding (GTAW), hot and cold wire feed laser welding features quicker, cleaner welds, lower dilution welds which lower costs and improves performance for clients.

Below we explain these processes in depth and compare their advantages and disadvantages.

What Is Hot and Cold Wire Feed Welding?

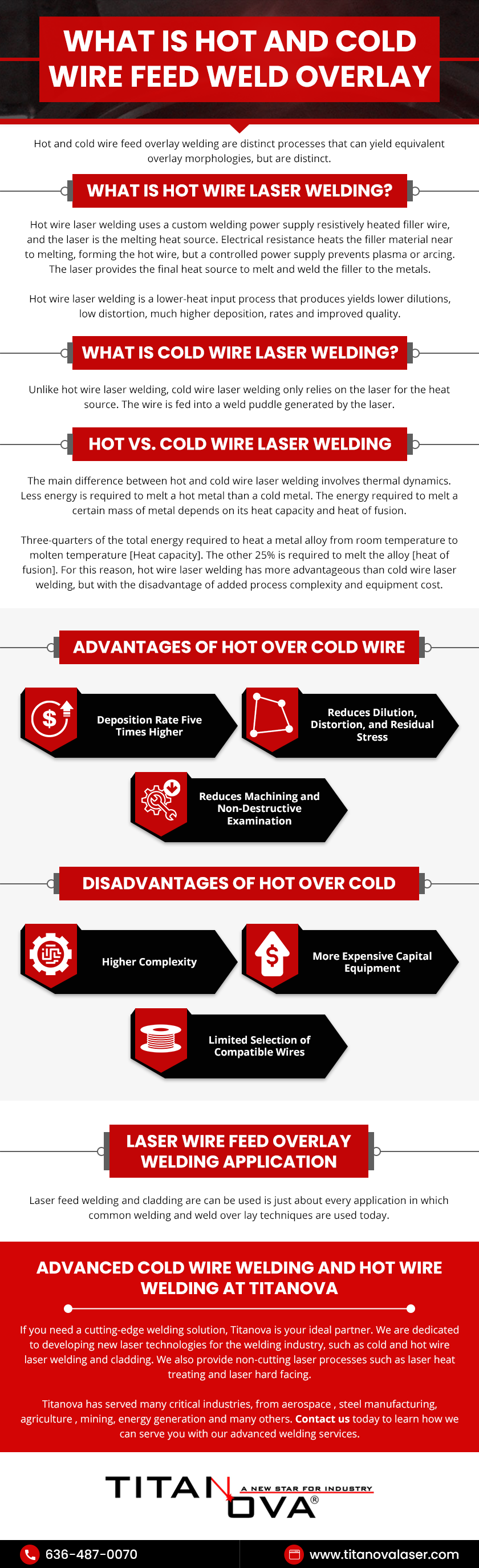

Hot and cold wire feed welding are distinct processes that yield near-perfect fillet welds and minimal distortions.

What Is Hot Wire Laser Welding?

Hot wire laser welding uses a custom welding power supply resistively heated filler wire, and the laser is the melting heat source. This combination promotes accurate weld location placement. Electrical resistance heats the filler material near to melting, forming the hot wire, but a controlled power supply prevents plasma or arcing. The laser provides the final heat source to melt and weld the filler to the metals.

Hot wire laser welding is a lower-heat input process that produces yields lower dilutions, low distortion, and improved quality.

What Is Cold Wire Laser Welding?

Unlike hot wire laser welding, cold wire laser welding only relies on the laser for the heat source. The wire is fed into a weld puddle generated by the laser.

Hot vs. Cold Wire Laser Welding

The main difference between hot and cold wire laser welding involves thermal dynamics. Less energy is required to melt a hot metal than a cold metal. The energy required to melt a certain mass of metal depends on its heat capacity and heat of fusion.

Three-quarters of the total energy required to heat a metal alloy from room temperature to molten temperature [Heat capacity]. The other 25% is required to melt the alloy [heat of fusion]. For this reason, hot wire laser welding has more advantageous than cold wire laser welding, but with the disadvantage of added process complexity and equipment cost.

Advantages of hot over cold wire

- Deposition rate five times higher

- Reduces dilution, distortion, and residual stress

- Reduces machining and non-destructive examination

Disadvantages of hot over cold

- Higher complexity

- More expensive capital equipment

- Limited selection of compatible wires

Laser Feed Welding Applications

Laser feed welding and cladding are can be used is just about every application in which common welding and weld over lay techniques are used today.

Advanced Cold Wire Welding and Hot Wire Welding at Titanova

If you need a cutting-edge welding solution, Titanova is your ideal partner. We are dedicated to developing new laser technologies for the welding industry, such as cold and hot wire laser welding and cladding. We also provide non-cutting laser processes such as laser heat treating and laser hard facing.

Titanova has served many critical industries, from aerospace , steel manufacturing, agriculture , mining, energy generation and many others. Contact us today to learn how we can serve you with our advanced welding services.