Our extensive expertise in laser processing solutions, combined with comprehensive quality assurance and metallurgical capabilities, is why we are the leaders in the laser processing industry. We maintain rapid process development and fast turnaround times at low costs for our clients while continually improving our systems, and striving for 100% customer satisfaction.

Through the years, Titanova has been steadfast in our mission to provide services and products of the highest quality by ultimately meeting or exceeding our customers’ requirements.

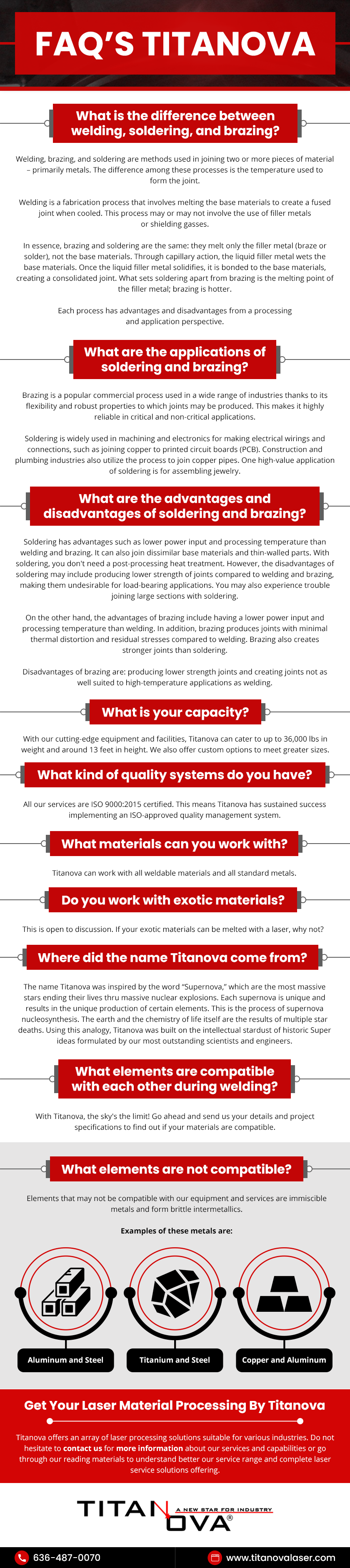

If you’re looking for clarification on laser processing for your project’s specific needs, you have come to the right place! In this blog, we are going to tackle some of the most Frequently-Asked-Questions we have received to enlighten and guide you through the process.

What is the difference between welding, soldering, and brazing?

Welding, brazing, and soldering are methods used in joining two or more pieces of material – primarily metals. The difference among these processes is the temperature used to form the joint.

Welding is a fabrication process that involves melting the base materials to create a fused joint when cooled. This process may or may not involve the use of filler metals or shielding gasses.

In essence, brazing and soldering are the same: they melt only the filler metal (braze or solder), not the base materials. Through capillary action, the liquid filler metal wets the base materials. Once the liquid filler metal solidifies, it is bonded to the base materials, creating a consolidated joint. What sets soldering apart from brazing is the melting point of the filler metal; brazing is hotter.

Each process has advantages and disadvantages from a processing and application perspective.

What are the applications of soldering and brazing?

Brazing is a popular commercial process used in a wide range of industries thanks to its flexibility and robust properties to which joints may be produced. This makes it highly reliable in critical and non-critical applications.

Soldering is widely used in machining and electronics for making electrical wirings and connections, such as joining copper to printed circuit boards (PCB). Construction and plumbing industries also utilize the process to join copper pipes. One high-value application of soldering is for assembling jewelry.

What are the advantages and disadvantages of soldering and brazing?

Soldering has advantages such as lower power input and processing temperature than welding and brazing. It can also join dissimilar base materials and thin-walled parts. With soldering, you don’t need a post-processing heat treatment. However, the disadvantages of soldering may include producing lower strength of joints compared to welding and brazing, making them undesirable for load-bearing applications. You may also experience trouble joining large sections with soldering.

On the other hand, the advantages of brazing include having a lower power input and processing temperature than welding. In addition, brazing produces joints with minimal thermal distortion and residual stresses compared to welding. Brazing also creates stronger joints than soldering.

Disadvantages of brazing are: producing lower strength joints and creating joints not as well suited to high-temperature applications as welding.

What is your capacity?

With our cutting-edge equipment and facilities, Titanova can cater to up to 36,000 lbs in weight and around 13 feet in height. We also offer custom options to meet greater sizes.

What kind of quality systems do you have?

All our services are ISO 9000:2015 certified. This means Titanova has sustained success implementing an ISO-approved quality management system.

What materials can you work with?

Titanova can work with all weldable materials and all standard metals.

Do you work with exotic materials?

This is open to discussion. If your exotic materials can be melted with a laser, why not?

Where did the name Titanova come from?

The name Titanova was inspired by the word “Supernova,” which are the most massive stars ending their lives thru massive nuclear explosions. Each supernova is unique and results in the unique production of certain elements. This is the process of supernova nucleosynthesis. The earth and the chemistry of life itself are the results of multiple star deaths. Using this analogy, Titanova was built on the intellectual stardust of historic Super ideas formulated by our most outstanding scientists and engineers.

What elements are compatible with each other during welding?

With Titanova, the sky’s the limit! Go ahead and send us your details and project specifications to find out if your materials are compatible.

What elements are not compatible?

Elements that may not be compatible with our equipment and services are immiscible metals and form brittle intermetallics. Examples of these metals are:

- Aluminum and steel

- Titanium and steel

- Copper and aluminum

- Others

What are thermal spray and laser cladding?

Thermal spraying refers to coating processes in which finely divided metallic or nonmetallic materials are rested in a molten or semi-molten state to form a coating. The coating material may be in the form of a ceramic rod, powder, wire, or molten material.

Laser Cladding is a welding process similar to electrical arc welding processes such as GTAW, TIG, MIG, and PTA in which the heat source is located where the overlay material and the workpiece surface come in contact.

The heat source is powerful enough to melt the coating material and a portion of the substrate to make a welded bond. However, melting as little of the workpiece substrate as possible is beneficial for distortion, intermetallic dilution, and structural defects.

Get Your Laser Material Processing By Titanova

Titanova is a full-service, ISO 9001:2015 certified laser job shop and a proud member of ASM, ASME, AWS, and NTMA. We supply non-cutting laser processes, including laser heat treating, laser glazing, laser welding, laser cladding, hard laser facing, laser clad overlay tubing, laser brazing, and laser additive machining services.

Titanova offers an array of laser processing solutions suitable for various industries. Do not hesitate to contact us for more information about our services and capabilities or go through our reading materials to understand better our service range and complete laser service solutions offering.