Welding is a fabrication process that employs heat to join two or more separate pieces. Currently, industry professionals utilize both traditional arc-based welding, spot welding, and laser welding methods for their operations. Both process variations offer unique characteristics that make them suitable for different cases. For example, traditional welding accommodates less precise workpiece fit-up, while laser welding offers greater processing speeds and lower risk of thermal distortion.

The following article summarizes the difference between traditional welding and laser welding services, including outlining their process, key advantages, and typical applications.

Traditional Welding Processes

There are several traditional welding methods still in use today, including:

- Tungsten inert gas (TIG) welding. This arc welding method employs the use of a non-consumable tungsten electrode to heat the workpiece and melt the filler (if present) to produce the weld.

- Metal inert gas (MIG) welding. This arc welding method uses a consumable wire component—serving as both the electrode and the filler material—to produce the weld.

- Spot-welding. This welding method utilizes a pair of electrodes to clamp workpieces together and pass an electric current between them to create the weld.

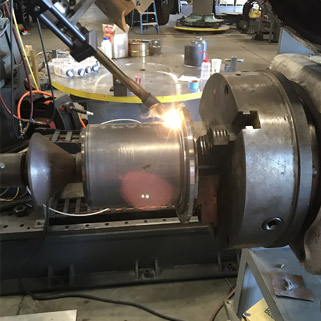

The Laser Conduction Mode Welding Process

Laser conduction mode welding is an advanced metal joining technique that uses a focused laser beam of an engineered spot size. During welding operations, the laser melt localizes areas of the workpiece and, if present, the filler material to form precise welds. Titanova offers both autogenous (without filler material) and non-autogenous options using either hot wire laser welding or cold wire laser welding. Depending on the geometry of the part, the joint, and the overall structural requirements, lasers can be used to replace traditional welding process.

<Learn more about hot and cold wire feed laser welding.>

Advantages of Traditional Welding

Laser welding offers several advantages over traditional welding methods. However, traditional welding processes remain an enduring fabrication solution for numerous industries for the following reasons:

- They are understood by the manufacturing community due to legacy operations.

- They accommodate less precise and accurate workpiece fit-up.

- They are easier to automate.

- They come with lower initial investment costs.

- They can be manually implemented.

Advantages of Laser Welding

Compared to traditional welding methods, laser welding has the following advantages:

- Less heat. In laser welding operations, the heat affected zone (HAZ) is much smaller and the total heat input is much lower than traditional welding operations.

- Lower risk of macro deflections and distortions. The above qualities also translate to a lower distortion stemming from thermal input. Less heat means less thermal stress, resulting in less damage to the workpiece.

- Faster processing times. Despite its higher initial tooling investment, laser welding can often prove more cost-effective than traditional welding due to its faster processing speed. Faster production speeds also mean greater production capacities, resulting in quicker turnaround.

- Greater suitability for thin metals. Due to its tailorable spot size, laser welding is an excellent joining method for thin or delicate metal parts. The spot size can be specifically designed to only melt the proper amount of metal to achieve the weld, thus minimizing the occurrence of heat-induced internal stresses, distortions, and defects.

Applications of Laser Welding

The better precision, control, and efficiency afforded by the laser welding process make it well-suited for the manufacture of the following:

- Hydraulic and fluid control parts

- Distortion critical thin shell assemblies

- Foils

- Fuel rails

- Medical instruments

- Stainless steel heat exchangers

- Thin gauge metal boxes

- Thin gauge parts

- Thin gauge tubing

Contact the Laser Welding Experts at Titanova Today

Although traditional welding methods have their advantages, laser welding has become a popular option for joining metals due to its accuracy, control, and ability to weld delicate or thin metal parts. If you’re looking for laser welding or other laser material processing services, consider Titanova. We have over 30 years of experience in the area. For information about our laser welding capabilities, visit our laser welding capabilities page or contact us today.

Comments are closed