Thermal Spray vs. Laser cladding

Comments Off on Thermal Spray vs. Laser claddingThis blog is meant to explain the differences between the thermal spray and laser cladding processes and help you understand the physical differences between each process. What is Thermal Spray? Thermal spraying refers to a group of coating processes in which finely divided metallic or nonmetallic materials [ceramics] are deposited in a molten or semi-molten […]

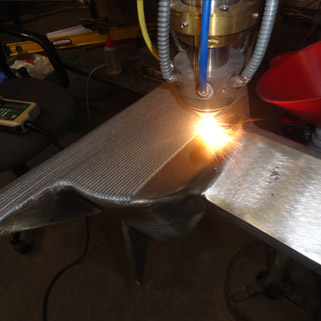

Introduction to the Laser Cladding Process

Comments Off on Introduction to the Laser Cladding ProcessLaser cladding—also referred to as laser metal deposition or Laser weld overlay—is a manufacturing technique used to add metal material to the surface of a component. It is generally used to create a protective coating that increases the functionality of the part or product. However, it can also be used to repair worn or damaged […]

Tags: laser cladding

Hardfacing Methods

Comments Off on Hardfacing MethodsHardfacing delivers a wear-resistant and hard coating of material on the surface of a worn component or a new component that will be subject to wear. There are various methods that can be used to apply the hardfacing layer. Common methods include: Arc Welding Oxygen-Acetylene Thermal Spraying Diode Laser Hardfacing The different hardfacing techniques provide […]

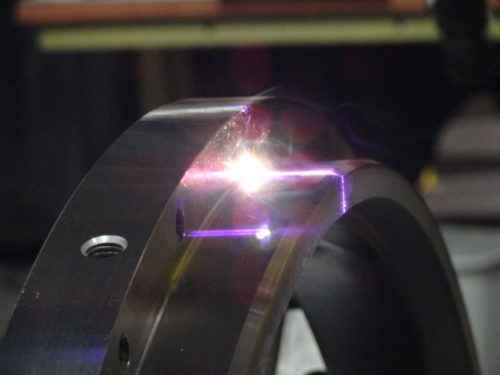

An Introduction to Laser Welding for Dissimilar Metals

Comments Off on An Introduction to Laser Welding for Dissimilar MetalsMany industries and applications require dissimilar materials to be joined for chemical, structural, and economic reasons. Combining dissimilar metals in a Weldment or for a weld overlay allow the use of the best properties of each metal. All industries benefit for this and is a primary importance when the overlay [cladding] is used in […]

Tags: dissimilar metals, laser welding

An Introduction to Autogenous Welding

Comments Off on An Introduction to Autogenous WeldingWelding is a manufacturing process used to join two or more individual pieces. It can be broadly categorized into two classifications: fusion welding and solid-state welding. Fusion welding encompasses all of the processes that utilize direct heat applied from an external source to fuse or melt contact surfaces of metals to weld them together, while […]

Tags: autogenous welding

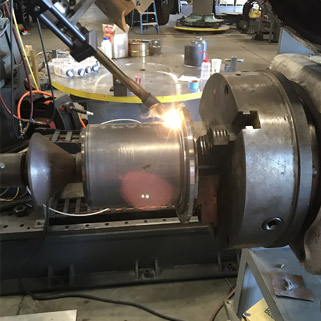

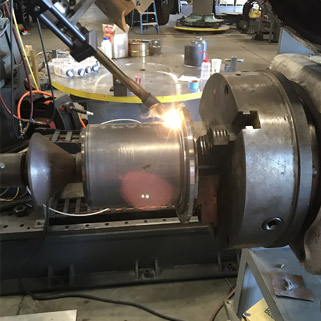

Guide to Laser Welding

Comments Off on Guide to Laser WeldingWhat Is Laser Welding? To understand laser welding we must step back and generally describe what welding is. Welding is joining similar materials of different shapes and similar melt temperatures. These materials are typically the same material. The welding process concentrates heat at the interface to melt the edges and upon solidification creates a structurally […]

Tags: laser welding

What Metals Can You Braze?

Comments Off on What Metals Can You Braze?Brazing is used to join metal parts and can be applied to a wide array of materials, like brass, copper, stainless steel, aluminum, zinc-coated steel, and ceramics. Laser brazing offers some distinct advantages in applications that require the joining of non-similar metals. Contact Us Laser Brazing Services What Is Brazing? Brazing is a process by […]

Tags: braze

What’s the Difference Between Hardfacing and Cladding?

Comments Off on What’s the Difference Between Hardfacing and Cladding?“Hardfacing” and “cladding” are two terms that are often used synonymously, not realizing they are distinctly different applications. If so, you are in good company, as it is a common misconception. Hardfacing is a welding process that applies a high-wear surface to add protection and extend the life of the object. The material welded […]

Tags: cladding, hardfacing, laser cladding, laser hardfacing

What Is Laser Hardening?

1 CommentLaser hardening—also referred to as laser case hardening—is a heat treating process used to improve the strength and durability of component surfaces. It employs the use of high-powered diode lasers that apply energy to heat localized areas of the component surface. As the lasers move across the surface it instantaneously heats the surface and […]

Tags: hardening, laser hardening

Traditional Welding vs. Laser Welding

Comments Off on Traditional Welding vs. Laser WeldingWelding is a fabrication process that employs heat to join two or more separate pieces. Currently, industry professionals utilize both traditional arc-based welding, spot welding, and laser welding methods for their operations. Both process variations offer unique characteristics that make them suitable for different cases. For example, traditional welding accommodates less precise workpiece fit-up, while […]